Making Extremely Wear-Resistant Plastic Gears with 3D Printing

Por um escritor misterioso

Descrição

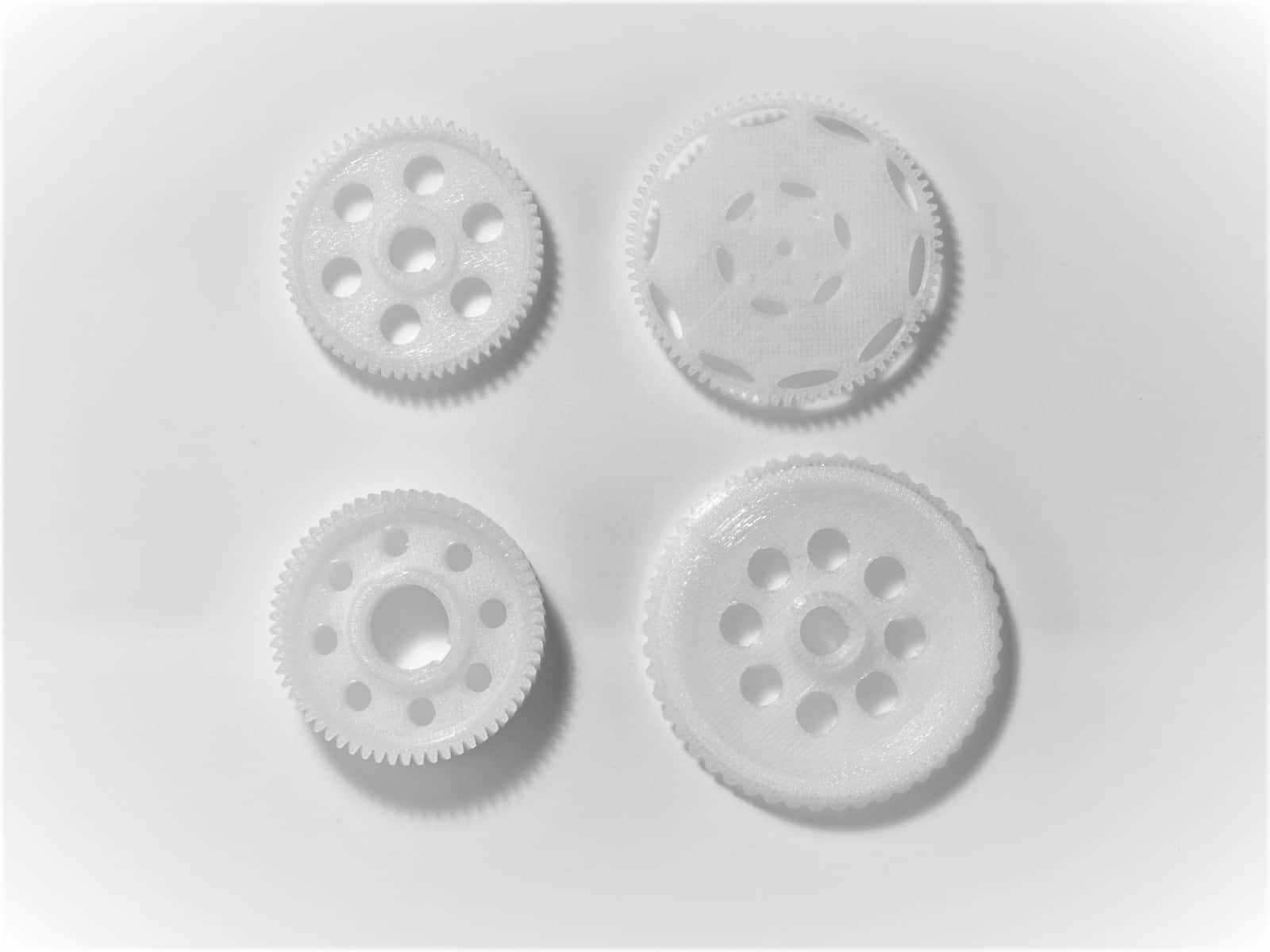

Using SLS with iglidur® high-performance polymers developed by igus allows manufacturers to make customized plastic gears.

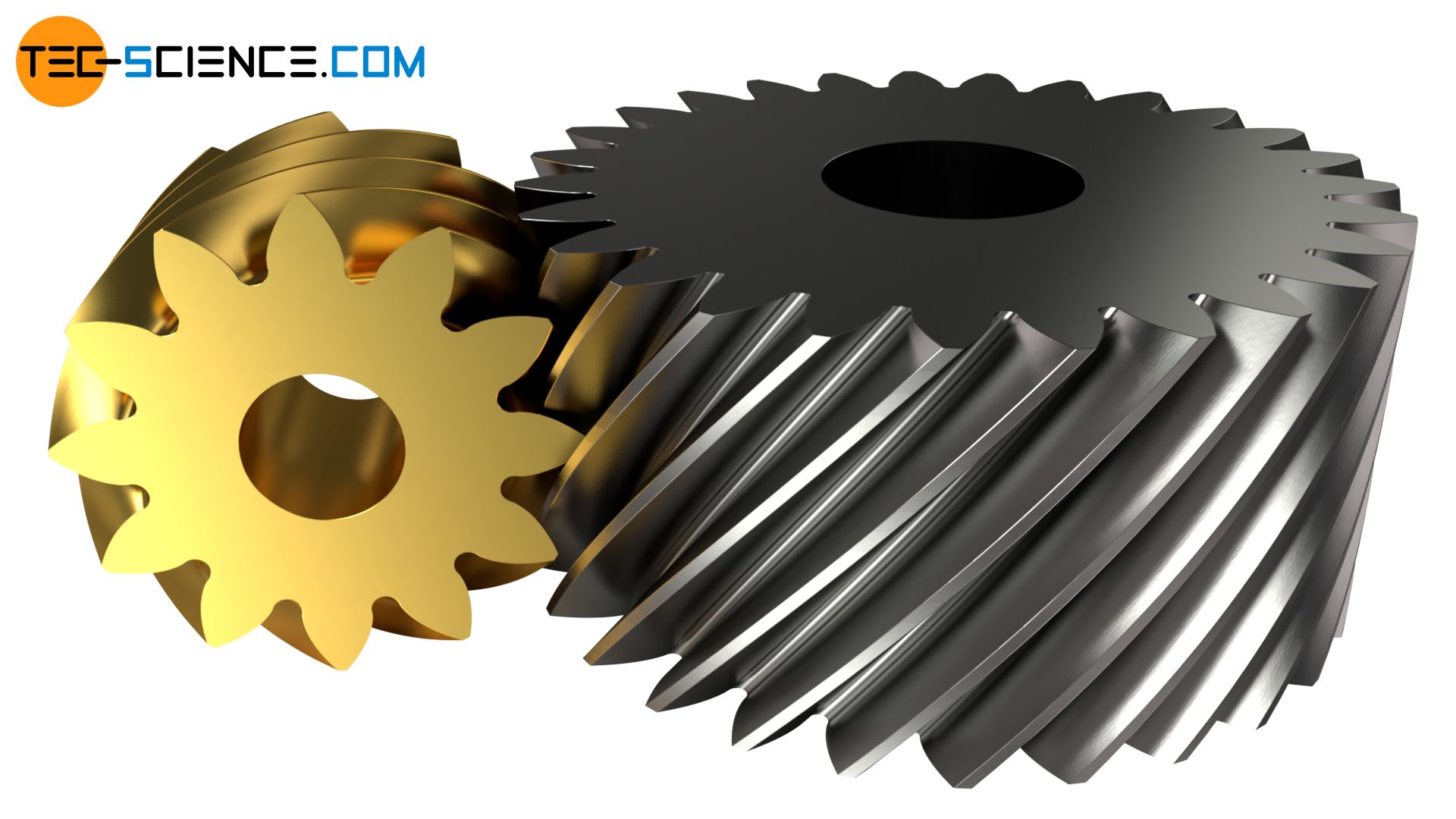

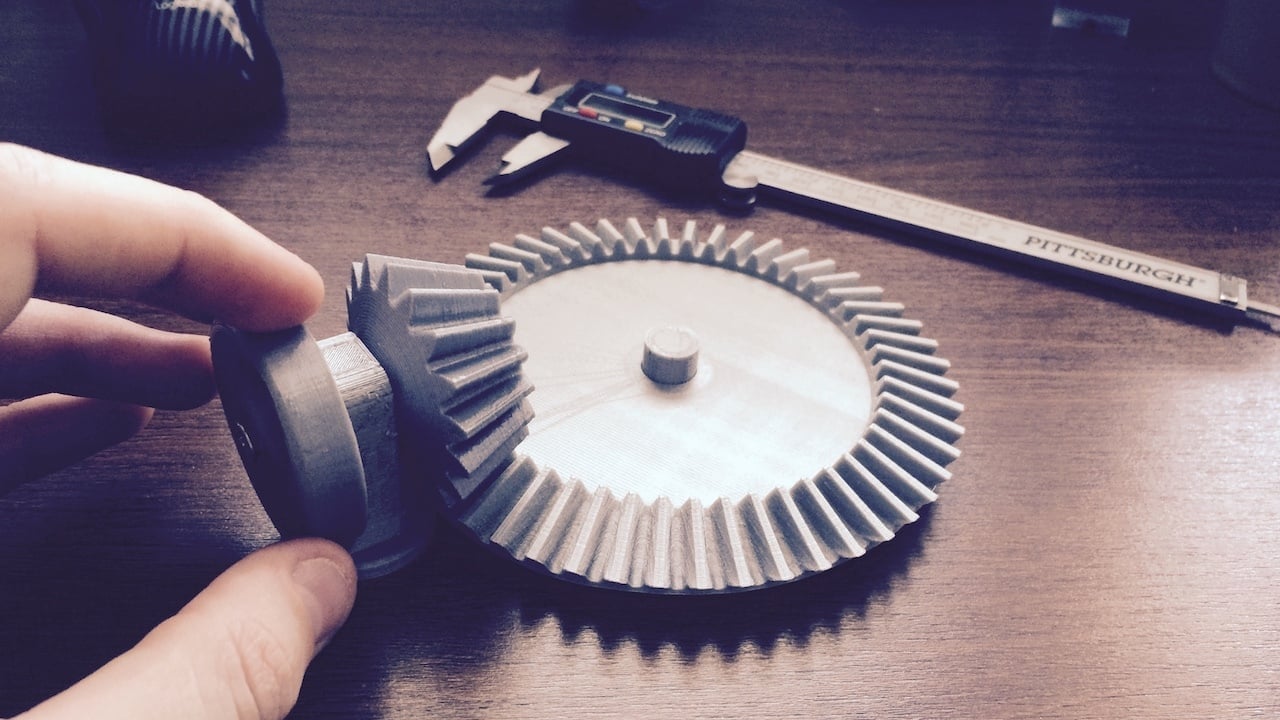

3D Printed Gears: How to Make Them

High-Quality Nylon 3D Printing

What Is the Strongest 3D Printer Filament?

5 Engineering Grade Plastics To Replace PLA - Fusion 3 Design

The Use of Plastic Gears in Industries

Guide to SLS Post-Processing Techniques: Media Blasting, Smoothing, Coating, Coloring, and More

3D Printer Gear 3D Printing - Sales - Repairs - Learn

3D Printed PLA Gear after 2 Years? - Spur Gear Tool in Fusion360

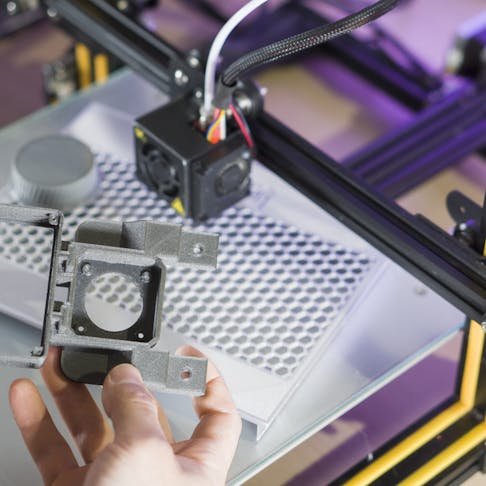

3D printed wear-resistant plastic gears for prototyping

Wear-resistant materials: A beginner's guide - UltiMaker

de

por adulto (o preço varia de acordo com o tamanho do grupo)